Welcome to kaishanindia

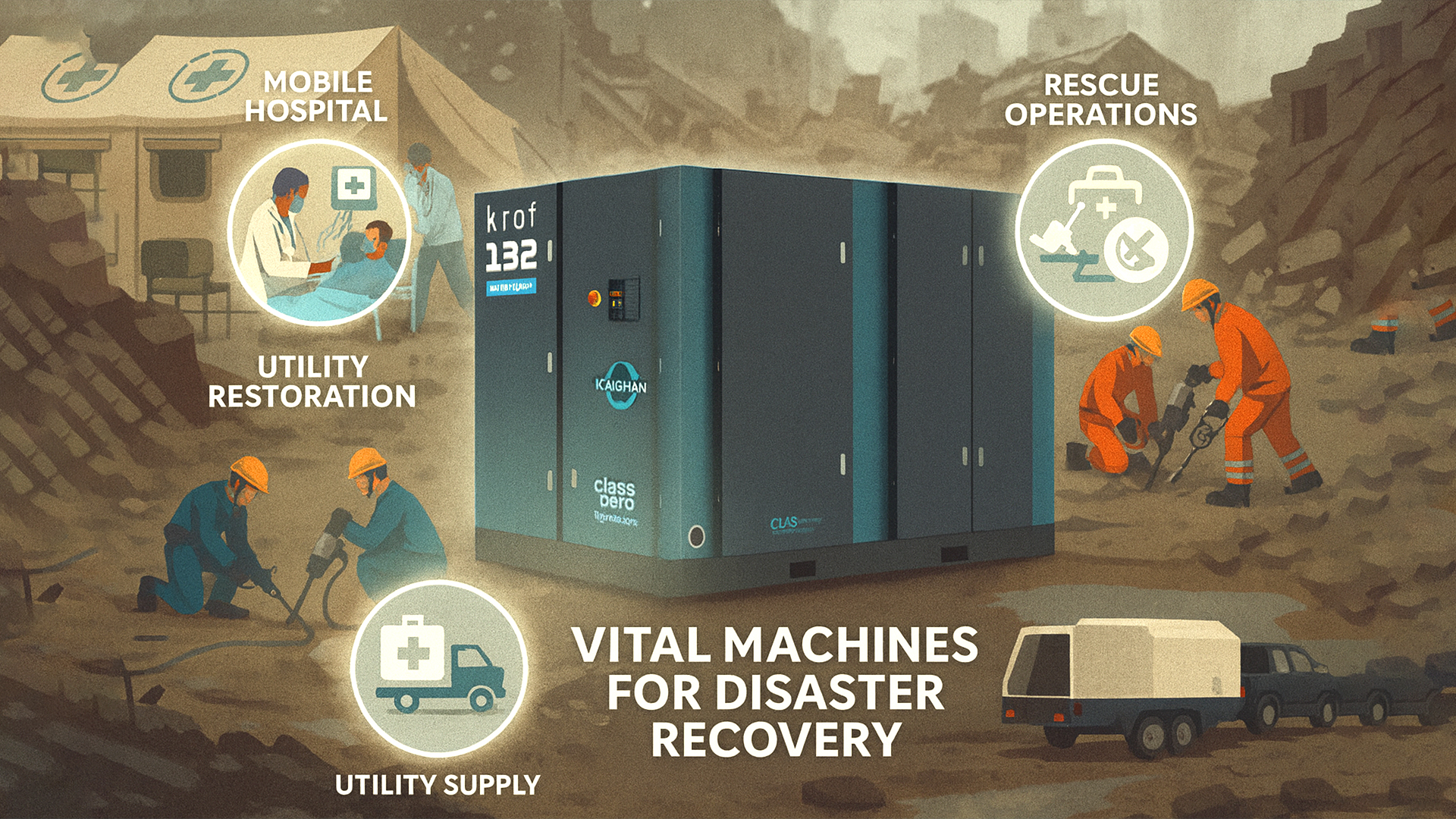

The Role Rotary Screw Air Compressors Play in a Disaster

Disasters, natural or man-made, disrupt lives, damage infrastructure, and halt essential services. In these high-pressure situations, reliable equipment becomes a lifeline. One such critical machine is the rotary screw air compressor. Known for its durability, continuous operation, and energy efficiency, it plays a vital role in response and recovery missions across sectors.

Powering Emergency Medical Equipment

Hospitals and mobile healthcare units rely heavily on compressed air for ventilators, oxygen delivery, suction devices, and pneumatic tools. Rotary screw compressors ensure uninterrupted, oil-free airflow, even during extended usage in emergency zones.

Supporting Rescue & Relief Operations

Rotary screw compressors power tools used in search and rescue—hydraulic cutters, pneumatic drills, and air lifts—especially in collapsed structures or blocked access zones. Their ability to operate non-stop makes them ideal for 24/7 emergency operations.

Fueling Temporary Power & Utility Services

In the wake of disasters, utility services like water supply, sanitation, and energy require quick restoration. Rotary screw compressors are used in pipeline pressurization, power generation support, and mobile utility units, helping communities get back on their feet faster.

Ideal for Harsh Environments

Disaster zones can be chaotic, with dust, debris, temperature fluctuations, and unstable power. Rotary screw compressors are built to endure extreme conditions, with minimal maintenance and robust performance.

Mobile and Ready for Deployment

Modern rotary screw compressors come in compact, portable skid or trailer-mounted versions, making them easy to deploy quickly wherever needed—from flood zones to remote earthquake-hit areas.

When every second counts, rotary screw air compressors provide the power, consistency, and reliability needed in disaster management. Their behind-the-scenes role might go unnoticed, but their impact on saving lives and restoring normalcy is nothing short of heroic.